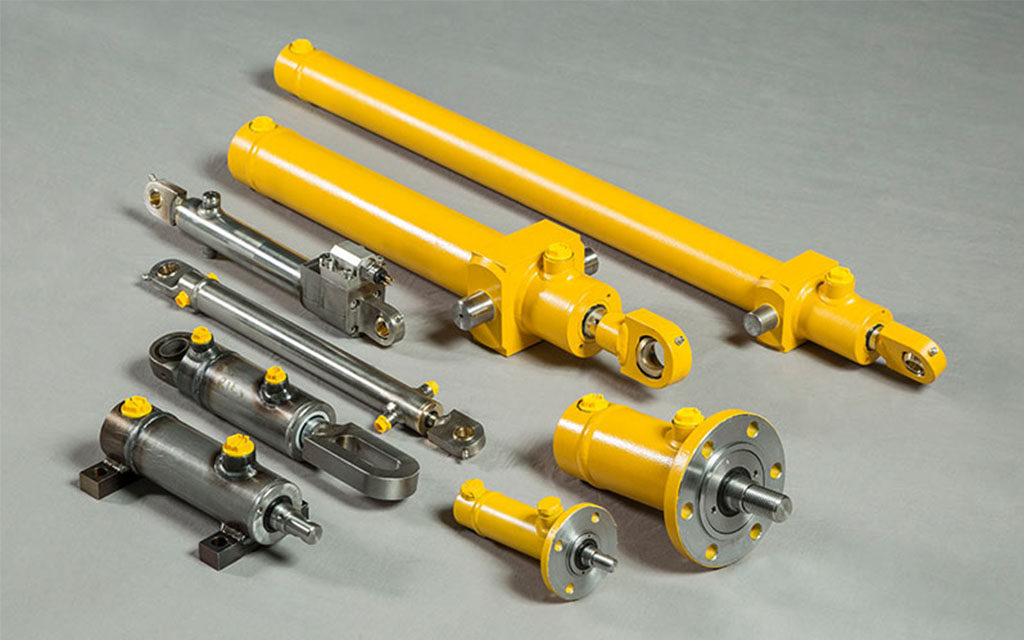

Hydraulic

Cylinders

What You Get

Tupelo Hydraulic has over 40 years combined experience, we have the ability to help you with all your hydraulic cylinder repair needs.

- Excellent Customer Service

- Fast Turn Around Time

- Warranty Coverage

Hydraulic Cylinder Support

Tupelo Hydraulics offer Hydraulic Cylinders and Hydraulic Cylinder Repair for the following Hydraulic Cylinder Machining and Hydraulic Support Manufacturers and Product Lines

See Manufacturers by clicking below

- Caterpillar is the world’s leading manufacturer of construction and mining equipment, engines, and diesel-electric locomotives. Their hydraulic cylinder assemblies are sold in both separate parts and in kits, with the option to buy new or remanufactured cylinders within any specification desired. They own more than 500 locations around the world and are headquartered from Deerfield, IL.

- Eaton Corporation is a global power management company and manufacturer of electrical and mechanical equipment and hydraulics, based out of Beachwood, OH. They manufacture and distribute the world’s largest selection of standard cylinders and provides customized cylinder solutions for interested buyers. Eaton serves the aerospace, building, data center, military, healthcare, mining, oil and gas, rail, residential, utilities, vehicles, and other vital industries.

- Parker Hannifin is a worldwide supplier of precision-engineered motion and control technology for the commercial, mobile, industrial, and aerospace markets. Parker is the leading global manufacturer of hydraulic cylinders and actuators for industrial applications, and have an extensive portfolio of accumulators, linear actuators, grippers, stages, and related equipment. They possess around 13000 global locations and are run from their headquarters in Mayfield Heights, OH.

- Bosch Rexroth Corp is a global engineering firm and manufacturer of control and motion systems used in industrial and mobile equipment, headquartered from Lohr am Main, Germany. Their products include assembly technologies, electric drives and controls, gears, industrial hydraulics, linear motion devices, molding and casting technology, robotics, and more, and have related services to ensure paired customers succeed in their applications.

- SMC Corporation is a Tokyo-based global manufacturer of automatic control equipment, sintered filters, and filtration equipment. They sell full pneumatic control systems and provide gauges, fittings, and control inputs needed to create a state-of-the-art air control system for any need. They provide their products to Japan, the US, Europe, and China and own factories in 30 countries.

- HYDAC is a fluid engineering solutions provider, with products ranging from components to complete hydraulic and electronic systems for numerous applications. Their product line includes filtration systems, sensors, controllers, cooling systems, accumulators, hydraulic cylinders, compact hydraulics, and more. They own 100 + branches all over the world and have their head office in Sulzbach, Germany.

- Standex International is a global manufacturing company with five segments in electronics, engraving, engineering, hydraulics, and food service equipment. Standex’s hydraulic division manufactures mobile cylinders for standard and custom applications, all made in the US and China to serve the truck, airline, mining, farming, and other industries. Their headquarters is in Salem, NH.

- Actuant Corporation, recently renamed to Enerpac Tool Group, is a premier industrial tool service company and manufacturer of hydraulic products around the globe. They create small to high tonnage hydraulic cylinders and related equipment, along with pumps, lifts, pullers, cutters, portable machine tools, and much more from their 28 facilities in 22 countries. They are headquartered in Menomonee Falls, WI.

- Weber-Hydraulik is a manufacturer of cylinders, manifolds, steering and suspension systems, valves, aggregates, and more, based out of Güglingen, Germany. Their products include cylinders, hydraulic control systems, valves, rescue equipment, and much more with additional customized options for any desired application. They serve the agriculture, crane, municipal, material handling, machinery, construction, truck, rescue equipment, and general industrial markets.

- Marrel is a global manufacturer of high-pressure hydraulics, skip loaders, tipper scissors, and other industrial vehicle-mounted equipment for government, construction, waste management, armed forces, and agricultural applications. Their manufacturing capabilities can create bores from 60 to 350 mm, rods from 32 to 200 mm, and stroke lengths up to 2500 mm, all equipped with built-in position sensors. They are a mainstay in the industrial heavy-duty hydraulics market and are headquartered in Andrézieux Bouthéon, France.

- Texas Hydraulics, of Temple TX, is a custom hydraulic cylinder manufacturer for OEMs, utilities, road service, mining, material handling, public service, underground construction, oil, gas, waste, transportation, agriculture, defense, and many more markets. They can walk customers through engineering to manufacturing to value-added services to ensure their standard or custom hydraulic system will fit the needs of their applications, and have an extensive catalog of configurable light-to-heavy duty cylinder options to choose from.

- Parker Hannifin, Parker’s Cylinder Division designs and manufactures the largest selection of actuation in North America. Cylinder Division offers a full range of standard NFPA hydraulic and pneumatic cylinders, mobile, compact and telescopic cylinders, helical rotary actuators, tilting couplers and custom cylinders.

- RAM Industries Inc. is a leader in hydraulic and pneumatic cylinder design and manufacturing. RAM has served OEMs for over 45 years in a wide range of industries with custom and innovative cylinder solutions. RAM’s success is built on its engineering and technical expertise. RAM designs and builds cylinders that meet your equipment fit and performance requirements. RAM prides itself on its quality products, service and customer support. Contact the RAM team of experts today!

- Hader Industries, Inc. We have the knowledge in the hydraulic cylinder industry that allows you to keep running efficiently and effectively for years. We don’t believe in making products that will break easily, and all our products can stand up to the harshest uses. We take the time to ensure that our designs are the best, and everything we make is made right here in the US! Find out more by contacting us today!

- A.L.E. Hydraulic Machinery Company LLC was incorporated in 1975. Since then we have been responding to our customers requests for services such as engineering services and fabrication.

- Advanced Fluid Systems, Inc. For over thirty years, Advanced Fluid Systems has been manufacturing custom hydraulic cylinders, pneumatic, lubrication, filtration and motion control systems. OEM trained & certified repairs and installation services. Our sales engineers are supported by in-house engineering and highly knowledgeable customer service departments. Contact us today for more information!

- Advanced Hydraulics, Inc. At Advanced Hydraulics, we offer heavy duty hydraulic cylinders and medium duty hydraulic cylinders, as well as hydraulic presses, pumps, valves, air cylinders, and more. We also provide a hydraulic cylinder repair service. With over sixty years in the industry, you can count on us for high quality products and service.

- Aggressive Hydraulics, Inc. is a leading manufacturer and designer of custom hydraulic cylinders. Since our founding in 2002 we have assembled a team of experienced professionals and talented engineers to assist us in creating the best hydraulic cylinders on the market. The component parts we offer include cylinder heads, end caps, mounts, pistons, ports, valve blocks, and other related accessories. To learn more about our hydraulic cylinders, visit our website.

- AiROYAL Mfg. Co. is a manufacturer of medium and heavy duty hydraulic cylinders, custom hydraulic cylinders, welded hydraulic cylinders, telescopic hydraulic cylinders, special hydraulic cylinders, high pressure hydraulic cylinders, small bore hydraulic cylinders and standard hydraulic cylinders. We also have both single- and double-acting cylinders.

- Al Xander Company, Inc. is a second generation family business, hydraulics and pneumatics distributor and manufacturer of pneumatic valves, controls and air line accessories. We pride ourselves on our largely stocked quality products. Contact us today for availability and pricing of a variety of components including air and hydraulic cylinders, o-rings, quick disconnect couplings and pressure gauges.

- Alkon Corporation is a leading manufacturer of custom hydraulic cylinders, special hydraulic cylinders and low pressure cylinders. Currently, we have 20,000 hydraulic cylinders in stock. Honed brass tubing construction equals longer lasting cylinders. We offer the best in quality, service and delivery.

- Anker-Holth™ is a manufacturer of a variety of hydraulic cylinders, including our mill duty cylinders, high-pressure cylinders, rotating cylinders, casting cylinders, torpedo cylinders, tie-rod cylinders and more. We will also build a cylinder according to your system parameters.

- Atlas Cylinders, a division of Parker Hannifin, is a manufacturer of heavy duty tie-rod custom hydraulic cylinders with bore sizes from 1” – 48”. Our special hydraulic cylinders and small hydraulic cylinders are used all over the world. Our cylinders are the major source for Boeing.

- Aurora Air Products is a family-owned and -operated company specializing in the manufacture of air cylinders, pneumatic cylinders, hydraulic and stainless steel cylinders. You can choose a device from our extensive catalog or receive assistance building your own.

- B&H Machine, Inc. A progressive reputation in cylinder manufacturing for over 40 years, B&H means “PRECISION” & “QUALITY” when it comes to heavy duty mill type, Pathon line & special design air & hydraulic cylinders, with a specialty in large bore & long stroke cylinders plus repair, rebuild, refurbish & modify all types & all manufacturers cylinders. Your go-to source for the most difficult cylinder requirements!

- Bailey International LLC is recognized for “best in class” hydraulic cylinders of all types and sizes, and settles for nothing less than total customer satisfaction. Our product line includes Bailey brands Chief® and Maxim®, Prince cylinders, telescopic cylinders, surplus and custom cylinders. See what we can ship immediately or how we can customize to your specs. Economically priced for one to thousands!

- Bay Hydraulics, Inc. For expert hydraulic equipment & servicing, Bay Hydraulics repairs & sells all brands of hydraulic motors, pumps, valves, cylinders and more. We not only rebuild your hydraulic motor but also do hydraulic testing to 150 HP and 5000 PSI. Our field service offers complete hydraulic trouble-shooting.

- Berendsen Fluid Power is one of the largest distributors of pneumatic and hydraulic products in North America. We distribute from quality manufacturers products such as hydraulic cylinders, hydraulic pumps, hydraulic motors, hydraulic valves, filters and more. Visit our website for more information.

- Best Metal Products Co. meets exact OEM specifications for custom hydraulic cylinders & hydraulic rams with superior service & turnaround. For the highest quality single, double acting, welded, telescopic & mobile cylinders in a broad range of configurations for high & low duty uses, trust our more than 50 years of expertise. Our continual refining of processes equals the best quality cylinder.

- Bimba Manufacturing Company produces air cylinders, stainless steel air cylinders, rodless cylinders and a variety of other cylinders. We provide custom-designed air cylinders, quick delivery and a company-wide commitment to quality. Contact us for your cylinder needs today!

- Bosch Rexroth Corporation, Pneumatics Division With 60 years experience manufacturing and distributing innovative air cylinders and valves, Bosch Rexroth offers standard and custom solutions for all industries. Cylinder types include NFPA, rodless, micro and mini, ISO/VDMA, octagon, twin rod, slides and pneumatic cylinders. We offer brass cylinders & stainless steel cylinders. Try our on-line configurators! We strive for customer satisfaction.

- Brenner-Fiedler & Associates, Inc. has been a leading automation and pneumatic solution provider for well over seven decades.The company has earned multiple certifications from ISO for their quality. Their panel shop focuses on creating world class material for product line like ABB, Kawasaki etc. If you are looking for good quality and affordable automation/ pneumatic related products then Brenner – Fiedler is the right place for you.

- Buffalo Hydraulic – For over 60 years, our company has offered hydraulic solutions to complex high pressure problems. We distribute products such as hydraulic cylinders, hydraulic presses, hydraulic pumps, hydraulic valves (both direction and solenoid), control valves, flow valves and more. We also can custom build pneumatic and hydraulic valves.

- C & C Hydraulics, Inc. For 30 years, C & C Hydraulics has been serving the hydraulic system needs of its customers throughout New England. We offer several product lines of hydraulic motors. We also repair hydraulic motors, cylinders and pumps, as well as steering gears and parts. Contact us for free pickup and delivery.

- CAL-WEST Machining Inc. Here at CAL-WEST Machining Inc. we offer a comprehensive line of hydraulic cylinders. These quality products can be tailored to your exact needs. There is no project size too big or too small for our company, we promise to supply your needs no matter what. It is our mission to create a lasting relationship with our customers and we will always support your projects. Please give us a call today to learn more information!

- Canadian Tool & Die – We have extensive experience in the manufacturing of hubs, spindles, wheels, OEM cylinders and replacement cylinders for agricultural and industrial use. We maintain rigid quality standards through all phases of production, thus, Canadian Tool & Die has built a reputation for quality, dependability and service throughout Canada and the United States.

- Carlson Hydraulics, a division of Squires Corp., is a leading manufacturer of welded hydraulic cylinders, heavy duty hydraulic cylinders, custom hydraulic cylinders and high pressure hydraulic cylinders. We can also produce your cylinder in a custom size to suit your particular specifications. Our staff is on hand to assist you with any inquiries. Call Carson and speak to a representative today!

- Cessna hydraulic cylinders

- Vickers hydraulic cylinders

- Parker hydraulic cylinders

- Heil hydraulic cylinders

- Monarch hydraulic cylinders

- Caterpillar hydraulic cylinders

- john deere hydraulic cylinders

- komatsu hydraulic cylinders

- kobelco hydraulic cylinders

- link belt hydraulic cylinders

- dawoo hydraulic cylinders

- hyundai hydraulic cylinders

- kawasaki hydraulic cylinders

- Bobcat Company hydraulic cylinders

- Bucyrus International hydraulic cylinders

- Case CE hydraulic cylinders

- CNH Global hydraulic cylinders

- DONEX hydraulic cylinders

- Doosan Infracore hydraulic cylinders

- ENMTP hydraulic cylinders

- HEPCO hydraulic cylinders

- Hitachi Construction Machinery hydraulic cylinders

- SANY hydraulic cylinders

- Hydrema hydraulic cylinders

- Hyundai Heavy Industries hydraulic cylinders

- J. C. Bamford (JCB) hydraulic cylinders

- Kato Works hydraulic cylinders

- Komatsu Limited hydraulic cylinders

- LBX (Link-Belt) Excavators hydraulic cylinders

- ThyssenKrupp hydraulic cylinders

- KOBELCO Construction Machinery Co., Ltd. hydraulic cylinders

- Kubota hydraulic cylinders

- Liebherr hydraulic cylinders

- LiuGong hydraulic cylinders

- Lonking hydraulic cylinders

- L&T hydraulic cylinders

- Mahindra hydraulic cylinders

- Marion Power Shovel Company hydraulic cylinders

- Mitsubishi Heavy Industries hydraulic cylinders

- New Holland hydraulic cylinders

- Orenstein & Koppel (O&K) hydraulic cylinders

- Poclain hydraulic cylinders

- Samsung Group hydraulic cylinders

- Sany hydraulic cylinders

- SDLG hydraulic cylinders

- ST Kinetics hydraulic cylinders

- SUMITOMO hydraulic cylinders

- Shantui hydraulic cylinders

- Tata Hitachi Construction Machinery hydraulic cylinders

- Terex Corporation hydraulic cylinders

- Uralvagonzavod hydraulic cylinders

- Volvo Construction Equipment hydraulic cylinders

- Wacker Neuson hydraulic cylinders

- XCMG hydraulic cylinders

- XGMA hydraulic cylinders

- Yanmar hydraulic cylinders

- Yuchai hydraulic cylinders

- Zoomlion hydraulic cylinders

- Abex Denison Hydraulics

- Atchley Hydraulics

- Bosch Rexroth Hydraulics

- Caterepillar Hydraulics

- Cessna Hydraulics

- Charlynn Hydraulics

- Commercial Intertech Hydraulics

- Commercial Scheering Hydraulics

- Commercial-Parker Hydraulics

- Continental Hydraulics

- Continental Pumps

- Daikin Hydraulics

- Danfoss Hydraulics

- Denison Hydraulics

- Denison-Parker Hydraulics

- Dynett Hydraulics

- Dynapower Hydraulics

- Eaton Hydraulics

- GearTek Hydraulics

- Hitachi Hydraulics

- Hydreco Hydraulics

- John Deere Hydraulics

- Kawasaki Hydraulics

- Kawasaki Staffa Hydraulic Motors

- Kayaba Hydraulics

- Kobelco Hydraulics

- Komatsu hydraulics

- Linde Hydraulics

- LinkBelt Hydraulics

- Mitsubishi Hydraulics

- Moog Hydraulics

- Oilgear Hydraulics

- Parker Hydraulics

- Parker-Servo Valves

- Racine Hydraulics

- Rexroth Hydraulics

- Samsung Hydraulics

- Sauer Danfoss Hydraulics

- Sauer Sundstrand Hydraulics

- Sunfab Hydraulics

- Uchida Hydraulics

- Vickers Hydraulics

- Volvo Hydraulics

- White Hydraulics

specializing in Hydraulic Cylinder repair

We invite you to explore the site and learn about us and our distinctive products, services, initiatives, and our history of excellence. As one of the World’s premier providers of hydraulic cylinders and our rebuild exchange services, we offer a full range of diagnostics, quality assurance, and buyer programs. At Tupelo Hydraulic Sales & Service we constantly strive to anticipate and serve the needs of our customers. In response to that need, Tupelo Hydraulic Sales & Service offers a “Short-Time” exchange program and a guarantee on all rebuilt products and services. We understand that time is more valuable than money.

Types of Hydraulic Cylinders

Learn more by clicking below

use hydraulic pressure to actuate the rod to extend and retract in both directions.

are designed for high pressures, high flows and rugged environments. Heavy duty cylinders are particularly suited to demanding industrial and mobile applications.

have significantly smaller and lighter designs than standard cylinders, which saves substantial weight and space in equipment. High pressure hydraulic cylinders are used in applications that need high forces and short or medium strokes, such as material testing and material transforming.

make the appartus that changes hydraulic fluid into mechanical power.

are short, cylinder shaped discs housed within cylinder barrels in order to compartmentalize the enclosed space within hydraulic cylinders.

are the large output pistons.

are devices that convert pressured fluid into mechanical power. Hydrolic is a common mispelling of hydraulic.

are designed for a multitude of applications in which a large force is required in both the push and pull directions.

are used in many applications, such as snowplows, construction equipment, personnel lifts and material handling equipment.

are manufactured and installed in older equipment with outdated cylinders. Replacement cylinder manufacturers offer products that will update machinery with the newest cylinder technology.

use hydraulic pressure to actuate the rod in only one direction.

can have strokes of less than an inch and are used in applications that require extreme precision.

are linear actuators designed specifically for highly corrosive environments as well as those where hygienic cleaning is essential to industrial processes.

are two-way hydraulic cylinders that provide a faster starting stroke and a subsequent, more powerful working stroke.

have multiple stages which enable longer strokes to be achieved, while utilizing less space.

have their head gland threaded on and the threads are protected by an o-ring.

use one or more steel rods, which are installed on the outside diameter of the cylinder housing, to provide extra stability. Cylinder tie-rods commonly bear a large portion of the applied load.

are made of a heavy duty, smooth welded housing for increased stability. Most housings of hydraulic cylinders are made of multiple parts, but not in the case of welded cylinders.

Tupelo Hydraulics offer's repair of all types of Hydraulic Cylinders

Many new types of Hydraulic Cylinders are offered by us

No Hydraulic Cylinder is too large or too small for Tupelo Hydraulic Service. We can accommodate all your Hydraulic Cylinder Repair needs.

Hydraulic Cylinder Applications

Learn more by clicking below

- Barber-Greene Pavers Sundstrand Hydraulic Cylinder Repair

- Blaw-Knox Pavers Dynex-Rivett Cylinder Repair

- Bomag Rollers Linde, Rexroth, Poclain Cylinder Repair

- Case Backhoe Webster, Commercial Cylinder Repair

- Case Track Loaders Sundstrand Cylinder Repair

- Case Dozer Sundstrand Cylinder Repair

- Case Wheel Loader Commercial Cylinder Repair

- Case Excavator Linde, Kawasaki Cylinder Repair

- Case Skid Loaders Sundstrand Cylinder Repair

- Caterpillar Dozer Linde, Rexroth, Tyrone, Vickers Cylinder Repair

- Caterpillar Track Loaders Cat, Linde, Vickers, Tyrone Cylinder Repair

- Caterpillar Excavators Linde, Rexroth, Kawasaki, Cat Cylinder Repair

- Caterpillar Milling Machine Sundstrand, Ross Cylinder Repair

- Caterpillar Motor Graders Vickers Cylinder Repair

- Caterpillar Scrapers Tyrone, Vickers Cylinder Repair

- Caterpillar Backhoe Rexroth, Vickers Cylinder Repair

- Caterpillar Wheel Loaders Vickers, Tyrone, Linde Cylinder Repair

- Daewoo Excavator Linde, Kawasaki Cylinder Repair

- John Deere Backhoe Deer, Oil Gear (Hydura) Cylinder Repair

- John Deere Dozer Sundstrand Cylinder Repair

- John Deere Track Loader Sundstrand Cylinder Repair

- John Deere Wheel Loader Sundstrand, Tyrone, Rexroth Cylinder Repair

- John Deere Excavator Linde, Uchida, Hitachi, Kawasaki Cylinder Repair

- Dresser Track Loader Linde Cylinder Repair

- Gradall Excavator Commercial, Rexroth, KYB Cylinder Repair

- Grove Excavator Commercial Cylinder Repair

- Hamm Rollers Linde Cylinder Repair

- Hitachi Excavator Hitachi, Kawasaki Cylinder Repair

- Hyundai Excavator Kawasaki Cylinder Repair

- Ingersoll-Rand Roller Sundstrand, Poclain Cylinder Repair

- Kato Excavator Kawasaki Cylinder Repair

- Kobelco Excavator Kawasaki Cylinder Repair

- Komatsu Dozer tyrone, Commercial, Hydreco Cylinder Repair

- Komatsu Rollers Vickers, Sundstrand Cylinder Repair

- Komatsu Wheel Loaders Komatsu Cylinder Repair

- Komatsu Excavators Komatsu Cylinder Repair

- Liebherr Excavators Linde, Liebherr Cylinder Repair

- Liebherr Excavators Track Loader Linde Cylinder Repair

- Liebherr Track Loader Linde Cylinder Repair

- Linkbelt Excavator Linde, Uchida Cylinder Repair

- P&H Crane Rexroth, Tyrone, Commercial Cylinder Repair

- Putzmiester Concrete Pumps Rexroth Cylinder Repair

- Schwing Concrete Pumps Rexroth Cylinder Repair

- Volvo Wheel Loaders Tyrone, Vickers Cylinder Repair

- Volvo Read Dump Commercial Cylinder Repair

- Wirtgen Milling Machine Rexroth Cylinder Repair

How does a Hydraulic Cylinder work

It has previously been noted that “Pascal’s Law” applies to confined liquids. Thus, for liquids to act in a hydraulic fashion, it must function with some type of enclosed system. An enclosed mechanical system that uses liquid hydraulically is known as a hydraulic power pack or a hydraulic power unit. Generally speaking, these packs/units consist of a reservoir (to store unused hydraulic fluid), a pump (to supply the rest of the hydraulic system with fluid), various types of tubes (to transport the hydraulic fluid), and actuators (devices that actually convert the energy produced by hydraulic liquid flow into mechanical power.)

Hydraulic cylinders form a major type of hydraulic actuator. The other major type of actuator is a hydraulic motor. The main difference between hydraulic cylinders and hydraulic motors lies in the fact that hydraulic cylinders primarily produce linear mechanical motion while hydraulic motors primarily produce rotary mechanical motion.

Although a hydraulic power pack is designed overall to harness the energy of fluid transmission, the cylinders represent the part of the pack where energy conversion truly takes place. Within the cylinder (or cylinders, as there are sometimes several) is a gear system and two valves alongside the piston. On one end is the intake check valve, with the discharge check valve being located on the opposite end. (As with the cylinder, some systems have just one piston or gear cog while others have multiple.)

Within a hydraulic system, tubing and a pressure vessel (or hydraulic pump) are needed to store and transport the fluid. When pressurized hydraulic fluids are introduced to the vessel, it presses upon the piston and engages the attached rod. When the pump is working, the piston is withdrawn. This creates a vacuum that draws hydraulic fluid from the reservoir, through the hosing and intake valve and finally into the cylinder. When the piston is returned to its original position and the check valve closes, the fluid becomes pressurized. This pumping action is repeated at variable speeds until enough pressure has been built up in the cylinder to force the fluid to pass through the discharge valve. This creates the energy needed to work the attached machinery and move the intended load.

Direction is determined by what side of the piston meets with the pressurized fluid. Fluid above the piston will retract the rod, while fluid below it will cause it to extend. The introduction of various amounts of pressurized hydraulic fluid on either end controls the movement of the piston, rod and attached load.