Injection Molding

What You Get

Tupelo Hydraulics over 40 years combined experience, we have the ability to help you with all your injection molding needs.

- Excellent Customer Service

- Fast Turn Around Time

- Warranty Coverage

Injection Molding Applications

This process is used to create many things such as wire spools, packaging, bottle caps, automotive parts and components, toys, pocket combs, some musical instruments (and parts of them), one-piece chairs and small tables, storage containers, mechanical parts (including gears), and most other plastic products available today. This process is the most common modern method of manufacturing plastic parts; it is ideal for producing high volumes of the same object.

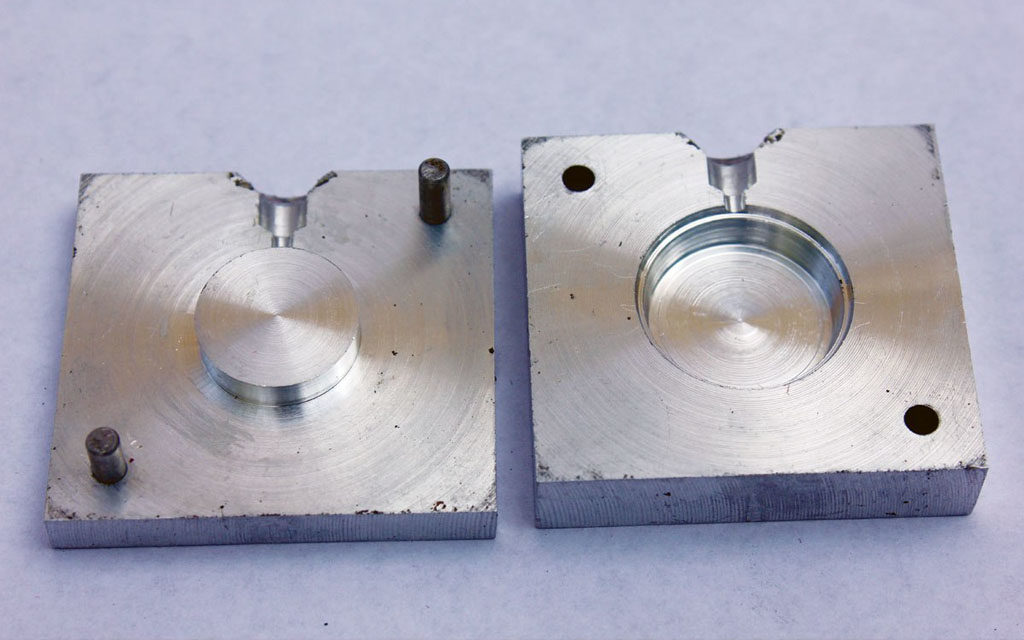

Mold

Parts

Machines

What is This Process

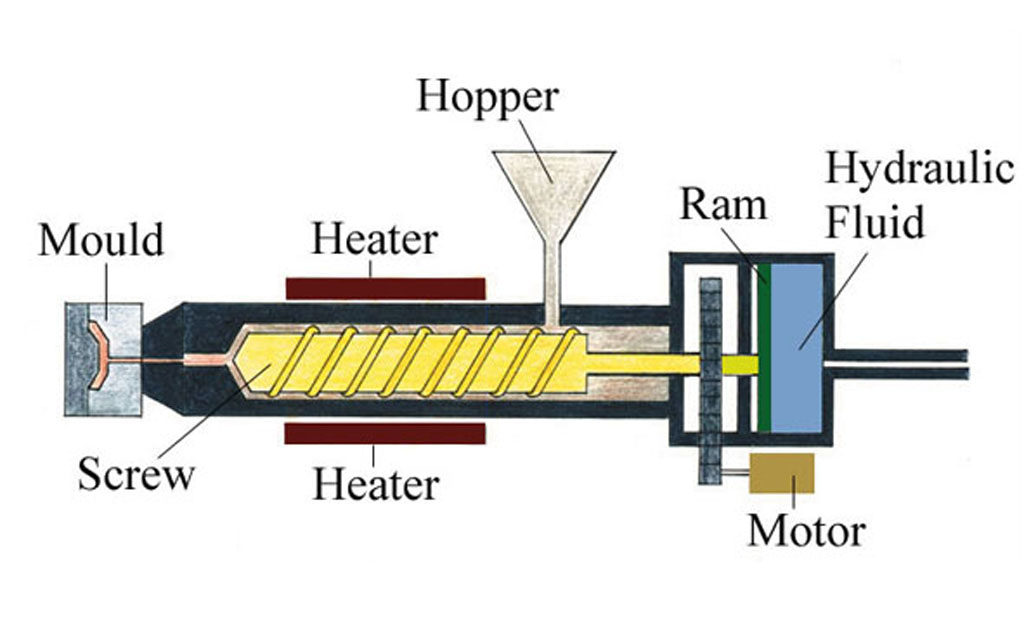

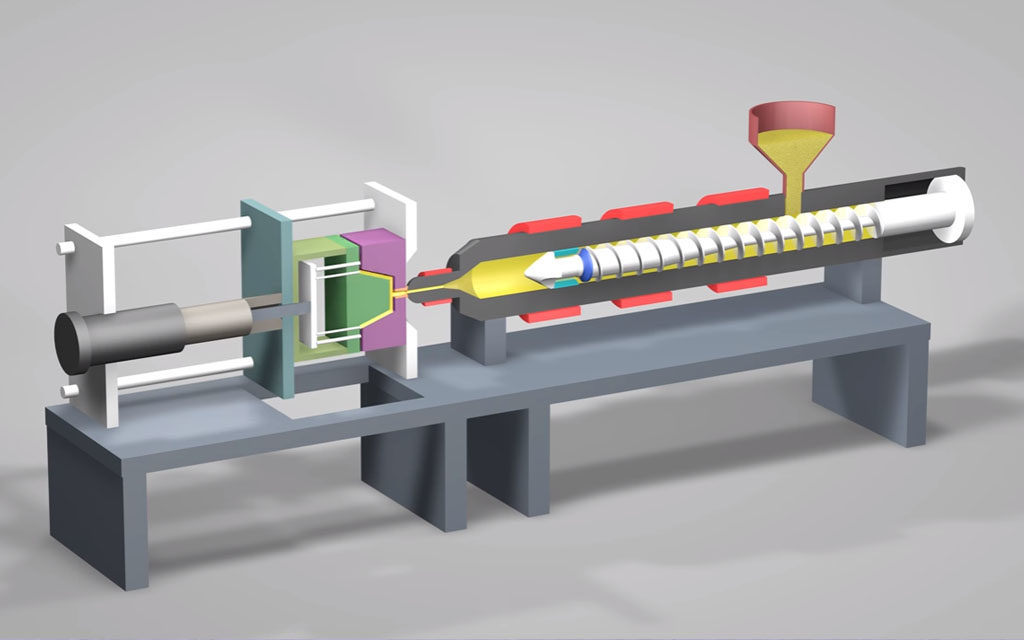

Injection molding is a manufacturing process for producing parts by injecting molten material into a mold. It can be performed with a host of materials mainly including metals, (for which the process is called die-casting), glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers. Material for the part is fed into a heated barrel, mixed (Using a helical shaped screw), and injected (Forced) into a mold cavity, where it cools and hardens to the configuration of the cavity.

After a product is designed, usually by an industrial designer or an engineer, molds are made by a mold-maker (or toolmaker) from metal, usually either steel or aluminium, and precision-machined to form the features of the desired part. This process is widely used for manufacturing a variety of parts, from the smallest components to entire body panels of cars. Advances in 3D printing technology, using photopolymers which do not melt during the injection molding of some lower temperature thermoplastics, can be used for some simple injection molds. Tupelo Hydraulic Sales and Service, LLC can help with all your needs.