When selecting a piston cup you need to consider the pressure range, temperature and the fluid, as well as air the pistons are working in. The main function is on the piston head, plunger or the ram, that is used in hydraulic situations. And take into consideration the industrial sealing plane of the perimeters also.

These types of pistons are cost efficient and have a good working life span. They work good in oil drilling, pumps and presses, mining equipment, off road equipment, valves and pneumatic equipment and so much more.

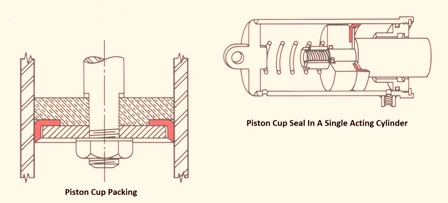

Packing for these pistons don’t need any machining of a recess. Can be put in resisting piston head or backing plate. The supporting plate is inside. The constricting seal is on the bottom. It lasts a long time. Very easy to put in.

If you need help with cylinders, piston or seals for them call us at 800-361-0068 or 662-871-8403