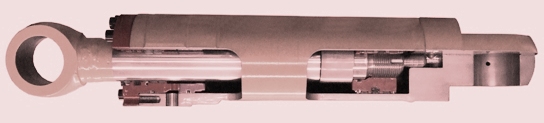

Here is a list of the parts that go into the makings of a cylinder.

ports and fittings

spherical rod eye

alignment fittings

spherical ball bushings

butt plates

polypak pistons

mp detachable mounts

cylinder head caps

head glands

eye brackets/clevis brackets

internal threaded ductile heads

cushions

cylinder base connection

Single-acting cylinders

Hydraulic fluid goes thru the port at one end , that elongates the rod by way of area difference. An external force, internal retraction spring or gravity returns the piston rod.

Double acting cylinder

Have a port at each end or side of the piston, that gives off hydraulic fluid for both the retraction and extension of the rod.

Tie rod cylinder

Tie rod style hydraulic cylinders use high strength threaded steel rods to hold the two end caps to the cylinder barrel. Mostly used in industrial factory settings.

Welded body cylinder

Welded body cylinders have no tie rods and the barrel is welded to the end caps and the ports . The front rod gland is most likely threaded into or bolted to the cylinder barrel. That lets the piston rod assy. and the rod seals to be taken out for service.

Special Hydraulic Cylinders

Telescopic cylinder

The length of a hydraulic cylinder is the total of the stroke, the thickness of the piston, the thickness of bottom and head and the length of the connections. Often this length does not fit in the machine. In that case the piston rod is also used as a piston barrel and a second piston rod is used.

Plunger cylinder

A hydraulic cylinder that doesn’t have a piston or has a piston but doesn’t have seals is a plunger cylinder. A plunger cylinder is only be used as a pushing cylinder; the maximum force is piston rod area multiplied by pressure. When it has that much pressure on it is usually a thick piston rod.

Differential cylinder

It acts like a normal cylinder when pulling. but if has to push, the oil from the piston rod side of the cylinder is not returned to the reservoir but goes to the bottom side of the cylinder. It does it in a way, the cylinder has to go faster, but the maximum pressure the cylinder can give is like a plunger cylinder

Position sensing “smart” hydraulic cylinder

It gets rid of the need for a hollow cylinder rod. They put in an external sensing “bar” using Hall Effect technology that senses the angle of the cylinder’s piston. This is done by the placement of a magnet that is in the piston. The magnet propagates a magnetic field through the steel wall of the cylinder, giving it a locating signal to the sensor.

Cylinder mounting methods

Flange mounts

cap end mounts for thrust loads and rod end mounts where putting heavy loads the piston rod in tension. Several types are head rectangular flange, head square flange or rectangular head. Flange mounts are used for when the mounting face attaches to a machine support member.

Side-mounted cylinders

The mounts have a turning moment as the cylinder administers pressure to a load, intensifying wear and tear. TO make sure this doen’t happen, designate a stroke at least as long as the bore size for side mount cylinders (heavy loading tends to make short stroke, large bore cylinders unreliable). Side mounts have to be aligned and the load supported and guided.

Centerline lug mounts

Takes on the centerline and has to have dowel pins to secure the lugs so that the movements at higher pressures or under shock conditions. Dowel pins keep it to the machine while it works at high pressure or under shock loading.

Pivot mounts

Takes on the cylinder centerline and lets the cylinder have a different alignment in one plane. Usual types are clevises, trunnion mounts and spherical bearings. They let the mounts on a cylinder to pivot, better used with rod-end attachments that pivot too. Clevis mounts work on most orientations and mostly made for short strokes and small- to medium-bore cylinders.

If you need more help with cylinders give us a call at 662-871-8403